Description

Kenya dig it? It’s been far too long since we last had a Kenyan coffee here! Expect big juicy fruit notes with sharp, crisp acidity and a clean, sticky body. This coffee really shines as a filter brew, where the clarity of flavour fully comes through.

GREEN PRICE: £10.04 per kilo

AMOUNT PURCHASED: 30kg

£13.00

Producer

Various SmallholdersCup Profile

Blood Orange,Cherry Jam, Caramel

Country

KenyaPreparation

WashedTerroir

Nyeri DistrictGenetics

SL34 & SL28Altitude

1,800mCup Score

86Description

Kenya dig it? It’s been far too long since we last had a Kenyan coffee here! Expect big juicy fruit notes with sharp, crisp acidity and a clean, sticky body. This coffee really shines as a filter brew, where the clarity of flavour fully comes through.

GREEN PRICE: £10.04 per kilo

AMOUNT PURCHASED: 30kg

‘Gatomboya’ is a Kikuyu word meaning ‘swamp’, due to the swampy area surrounding the site. The washing station is located in the Nyeri District, to the south of Mt Kenya. It is part of the Barichu Cooperative Society. The factory itself sits at 1,800 metres, and is around 2.5 miles from the town of Karatina. The 600 registered members cultivate coffee between 1,400 and 2,000 meter above sea level. The station processes around 600 tons of cherry annually which is harvested between Nov-Dec. The producers in the area mainly cultivate SL34 & SL28, alongside the newer Ruiru 11 variety in a terroir constituted of rich volcanic, sandy soil.

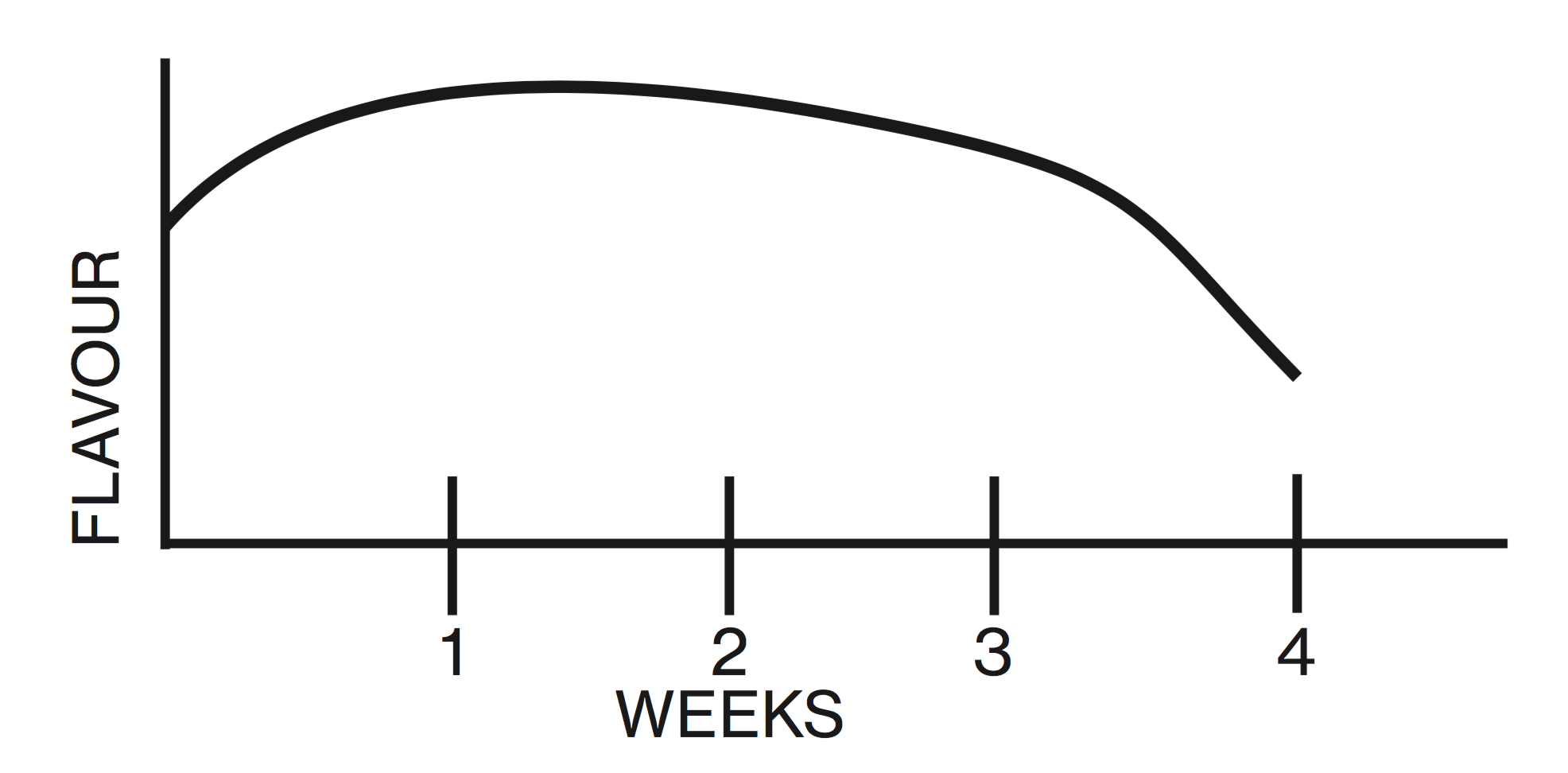

Both SL34 & SL28 cultivars have outstanding cup potential. They’re a personal favourite of ours owing to their natural sweetness and vibrant, fruity acidity. ‘AA’ refers to the grading system used for Kenyan coffees based on bean size uniformity. AA are large, round beans, and general considered to produce the highest cup quality. During processing, cherries are hand sorted and floated. Only ripe cherries are then pulped and fermented for 16-24 hours, before being washed clean and soaked for a further 8-14 hours. Afterward, they are laid to dry on raised beds. Factory staff rake the coffee frequently in order to ensure even drying. It is covered during the hottest time of day to maintain slow, even drying. After approximately 3 weeks, the coffee is likely to have reached optimal moisture content. It is then stored in the factory warehouse, ready to be delivered to the auction for marketing.